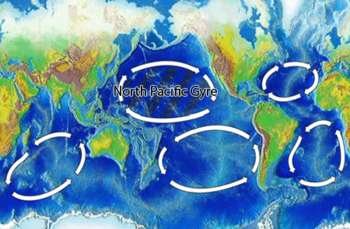

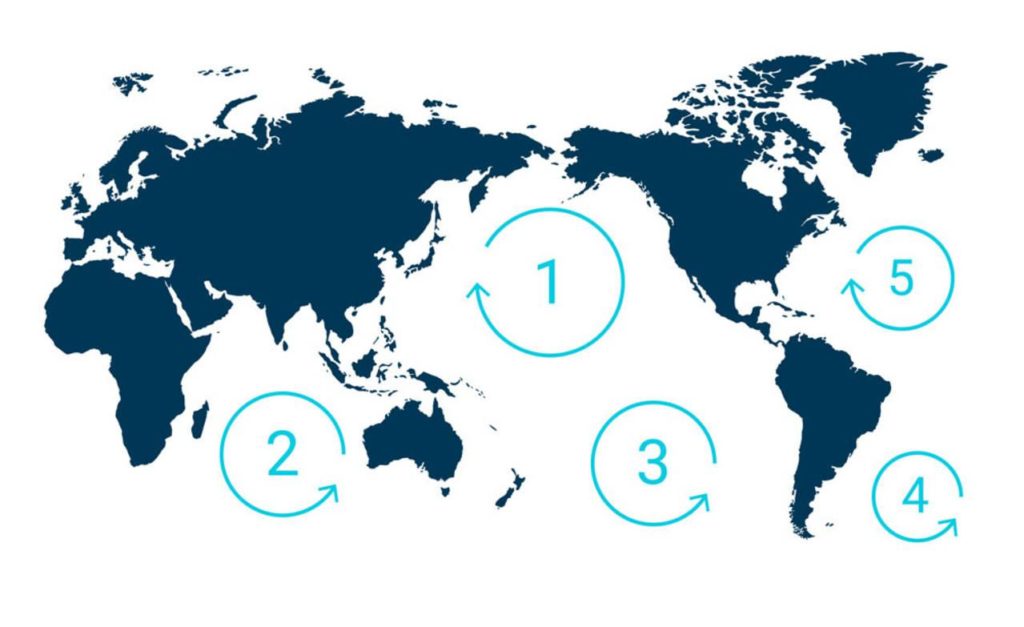

According to a three-year study published in Scientific Reports the world’s largest accumulation of ocean garbage is growing. The Great Pacific Garbage Patch, a collection of plastic, floating trash halfway between Hawaii and California, has grown to more than 600,000 square miles, about 1.6 million square kilometers, up to 16 times bigger than previous estimates a study found, 5.25 Trillion pieces and counting. The Great Pacific Garbage Patch (GPGP) is the largest of the five offshore plastic accumulation zones in the world’s oceans. That’s twice the size of Texas or three times the size of France, EQUIVALENT TO 500 JUMBO JETS. That is equivalent to 250 pieces of debris for every human in the world.

1.15 to 2.41 million tonnes of plastic are entering the ocean each year from rivers. More than half of this plastic is less dense than the water, meaning that it will not sink once it encounters the sea. The stronger, more buoyant plastics show resiliency in the marine environment, allowing them to be transported over extended distances. They persist at the sea surface as they make their way offshore, transported by converging currents and finally accumulating in the patch. Once these plastics enter the gyre, they are unlikely to leave the area until they degrade into smaller micro-plastics under the effects of sun, waves and marine life. As more and more plastics are discarded into the environment, micro-plastic concentration in the Great Pacific Garbage Patch will only continue to increase. Due to seasonal and inter-annual variabilities of winds and currents, the GPGP’s location and shape are constantly changing. Only floating objects that are predominantly influenced by currents and less by winds were likely to remain within the patch. Input of plastic in the patch is greater than the output. Unless sources are mitigated, this number will continue to rise.

The vast majority of plastics retrieved were made of rigid or hard polyethylene (PE) or polypropylene (PP), or derelict fishing gear (nets and ropes particularly). Ranging in size from small fragments to larger objects and meter-sized fishing nets.

Plastic in the patch has also been measured since the 1970’s and the calculations from subsequent years show that micro-plastic mass concentration is increasing exponentially – proving that the input of plastic in the patch is greater than the output. Unless sources are mitigated, this number will continue to rise.

Although scientists have known for decades about the accumulating mass of ocean debris and its deadly consequences for seabirds, fish, and marine animals, the science of sea trash is young and full of as-yet unsolved mysteries. Almost nothing was known about the amount of plastic in remote regions of the Southern Hemisphere, for example, until last year because few had ever traveled there to collect samples.

And though scientists know a great deal about the damage to marine life caused by large pieces of plastic, the potential harm caused by micro-plastics is less clear. What effect do they have on fish that consume them?

Marcus Eriksen says his research has helped fill in the outlines of the life cycle of ocean plastic. It tends to collect in the world’s five large gyres, which are large systems of spiraling currents. Then, as the plastic degrades into fragments, it falls into deeper water, where currents carry it to remote parts of the globe.

“These fragments are anywhere on the planet at this point,” he says. “We’re finding them everywhere.”

“If you have 200 million tons of plastic produced every year, researchers will arbitrarily estimate that 10 percent goes into the oceans,”85 percent of the world’s plastic is not recycled.

It’s not too difficult to surmise why so much plastic ends up in the ocean. ThePlastic Disclosure Project,a project run by Hong Kong-based advocacy groupOcean Recovery Alliance, estimates that 33 percent of plastic manufactured worldwide is used once, then discarded. To compound matters, 85 percent of the world’s plastic is not recycled.

Despite the magnitude of the numbers, Peter Ryan, a zoologist at the University of Cape Town, South Africa, says the problem can be solved. “Marine debris, should be an easy thing to deal with,” he says. “We have to sort out what to do with our rubbish.”

Impact On Wildlife

Plastic has increasingly become a ubiquitous substance in the ocean. Due to its size and color, animals confuse the plastic for food, causing malnutrition; it poses entanglement risks and threatens their overall behavior, health and existence.

84% OF SAMPLES CONTAINED TOXIC CHEMICALS IN EXCESS

Studies have shown that about 700 species have encountered marine debris, and 92% of these interactions are with plastic. 17% of the species affected by plastic are on the IUCN (International Union for Conservation of Nature) Red List of Threatened Species.

Not only does plastic pollution in the Great Pacific Garbage Patch pose risks for the safety and health of marine animals, but there are health and economic implications for humans as well.

Floating at the surface of the Great Pacific Garbage Patch (GPGP) is 180x more plastic than marine life. Animals migrating through or inhabiting this area are then likely consuming plastic in the patch. For example, sea turtles by-caught in fisheries operating within and around the patch can have up to 74% (by dry weight) of their diets composed of ocean plastics. Laysan albatross chicks from Kure Atoll and Oahu Island have around 45% of their wet mass composed of plastics from surface waters of the GPGP.

Since 84% of this plastic was found to have at least one Persistent Bio-accumulative Toxic Persistent Bio-accumulative Toxic (PBT) chemical, animals consuming this debris are therefore ingesting the chemicals attached to the plastic.

Fishing nets account for 46% of the mass in the GPGP and they can be dangerous for animals who swim or collide into them and cannot extract themselves from the net. Interaction with these discarded nets, also known as ghost nets ghost nets , often results in the death of the marine life involved.

Impact On Humans And Society

PLASTIC POLLUTION COSTS 13B DOLLARS PER YEAR

Once plastic enters the marine food web, there is a possibility that it will contaminate the human food chain as well. Efforts to clean and eradicate ocean plastic have also caused significant financial burdens.

Affects the Human Food-chain

Through a process called bio-accumulation, chemicals in plastics will enter the body of the animal feeding on the plastic, and as the feeder becomes prey, the chemicals will pass to the predator – making their way up the food web that includes humans. These chemicals that affected the plastic feeders could then be present within the human as well.

Understanding Toxicity

It is commonly known that harmful PBT (Persistent Bio-accumulative Toxic) chemicals are found in ocean plastics, so researchers at The Ocean Cleanup tested plastic samples from the expeditions for their chemical levels. These results have helped them to realize what chemicals are present in the patch and what that means for animals feeding there.

Plastics ranging from various type and size were analyzed by placing them in mixtures that would allow the various chemicals to be identified. A process known as Chromatography. They found through various tests that 84% of the plastics in the GPGP contain at least one type of PBT chemical.

Affects the Economy

The United Nations reported that the approximate environmental damage caused by plastic to marine ecosystems represents 13 billion USD. This figure included the cost of beach cleanups and the financial loss incurred by fisheries.

2015 – Mega Expedition

In 2015, 30 vessels and 652 surface nets, in parallel, crossed the GPGP as part of the Mega Expedition.

Numerous vessel owners offered the use of their ships for the mission. Of those ships, many carried behind them a Manta-trawl; including one mothership, the 171ft long Ocean Starr, which was able to carry two 6-meter-wide trawls and a survey balloon.

The fleet returned with over 1.2 million plastic samples that rendered an unprecedented amount of plastic measurements from the three months of study. Scientists present on the expedition noted that there was an alarming amount of plastic floating in the patch, and their preliminary findings indicated that there were more large objects than originally expected.

Introduction to HDPE

High-Density Polyethylene, usually shortened to HDPE or PEHD, is a plastic polymer with flexible properties which make it ideal for a wide range of applications.

High-density polyethylene, as the name suggests, has a higher specific density than low-density polyethylene, though this difference is only marginal. What really makes the difference in the physical properties of HDPE is the lack of branching, meaning it is light with a high tensile strength. Because there is no branching the structure is more closely packed, make HDPE a linear polymer. The branching can be controlled and reduced by using specific catalysts during production.

The amount of plastic out there is truly staggering to contemplate. Americans use 2.5 million plastic bottles every hour, and all that material doesn’t simply disappear into thin air after it has been thrown away. The vast amount of plastic piling up in landfills across the globe constitutes a major threat to the well-being of the Earth’s environment. LDPE and HDPE make up a substantial portion of the world’s plastic waste products. As highly durable non-biodegradable materials, they will be around for many years unless steps are taken to recycle them.

Properties and Applications of HDPE

HDPE has many advantageous properties that make it important in the manufacturing of different products. HDPE has a comparatively high density compared to other polymers, with a specific gravity of 0.95. HDPE is relatively hard and resistant to impact and can be subjected to temperatures of up to 248oF without being affected.

HDPE is not autoclavable, unlike Polypropylene (PP). Autoclaving conditions are used to sterilize products using high pressures and temperatures.

HDPE is recognizable by its opaque or translucent appearance.

These durable properties make it perfect for heavy duty containers and HDPE is primarily used for milk containers, as well as Tupperware, shampoo bottles, bleach bottles and motor oil bottles. Also, HDPE does not absorb liquid readily, making it good barrier material for liquid containers. Almost a third (about eight million tons) of HDPE produced worldwide is used for these types of containers.

Furthermore HDPE is an extremely resistant material to many chemicals, hence it widespread use in healthcare and laboratory environments. It is resistant to many acids, alcohols, aldehydes, esters, bases and oils.

Other uses for HDPE include: Plastic shopping bags, Trays, Tanks, Food containers (HDPE is approved for contact with food by many food advisory boards), Pipe fittings, Hinges, Cutting boards, Wear plates

Recycling of HDPE

HDPE is accepted at most recycling centers in the world, as it is one of the easiest plastic polymers to recycle. Most recycling companies will collect HDPE products and take these to large facilities to be processed.

First, the plastic is sorted and cleaned, to remove any unwanted debris. The plastic then needs to homogenized, so that only HDPE will be processed. If there are other plastic polymers in the batch, this can ruin the recycled end-product.

HDPE is then shredded and melted down to further refine the polymer. The plastic is then cooled into pellets which can be used in manufacturing.

Recycling plants can also benefit from the use of a baler, which can compress the post-consumer waste to minimize energy used in transport.

Small steps at home can also be taken to recycle HDPE. With regards to milk bottles, these can easily be reused if washed out thoroughly first. Equally, carrier bags can also be reused when going shopping. Many large supermarkets also offer collection points for used carrier bags to be recycled. Recycling of HDPE is aided by the resin code on the product, which is an indiscriminate number assigned to different plastic polymers to help separate plastics at the recycling stage. The resin identification code for high-density polyethylene is ‘2’.

The Environmental Benefits of Recycling HDPE

The worldwide market for HDPE is huge, with a market volume of around 30 million tons per year.

The amount of plastic used in plastic bags has reduced by around 70% in the last 20 years thanks to the introduction of reusable canvas bags and using biodegradable materials, but the majority of bags are still produced from HDPE. Furthermore, there is a growing market for HDPE containers in China and India due to increased standards of living, as well as a higher demand for HDPE pipes and cables due to rapidly growing industries.

HDPE is non-biodegradable and can take centuries to decompose, so it is imperative that these bags and containers are recycled and used again.

Recycling HDPE has many benefits. For example, it is more cost efficient to produce a product from recycled HDPE than it is to manufacture ‘virgin’ plastic.

HDPE, like many plastic polymers, is produced using considerable amounts of fossil fuels and it takes a total of 1.75kg of oil to manufacture just 1kg of HDPE.

- Recycling HDPE products takes about half as much energy as incineration disposal.

- Recycling HDPE helps reduce the expense associated with manufacturing products made from these materials.

- Recycling HDPE helps reduce the expense associated with waste disposal (e.g., landfill costs).

- It is cheaper to make HDPE from recycled matter than to use new materials.

Not only does recycling help the environment, it also provides extra income for businesses. Plastic scrap can be a useful revenue source.

Products Made from Recycled HDPE

The great thing about recycling is that it puts this old material to good use. You may be surprised at the wide variety of products made from recycled LDPE and HDPE. Below is a partial list of everyday products commonly manufactured with recycled plastic:

- Furniture

- Floor tiles

- Trash cans and crates

- Shipping envelopes

- Paneling

- Gardening tools

- Rope

- Toys

- Plastic lumber